- Time : Monday-Friday 09am-5pm

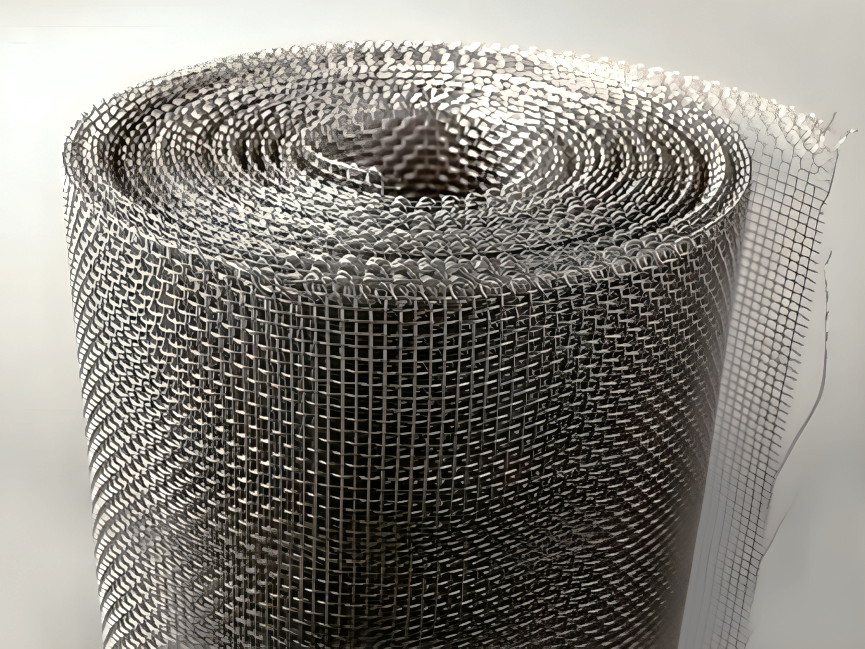

Our Vibrating Screen Mesh is engineered for high-impact screening applications where strength, durability, and accuracy are essential. Designed with larger opening sizes starting from 8 mm and wire diameters beginning at 4 mm, this mesh delivers superior material separation in heavy-duty operations.

Manufactured using premium Spring Steel, High-Carbon Steel, our vibrating screen mesh offers exceptional resistance to wear, vibration, and abrasion. It is widely used in stone crushers, mining, quarrying, aggregate processing, and industrial screening systems.

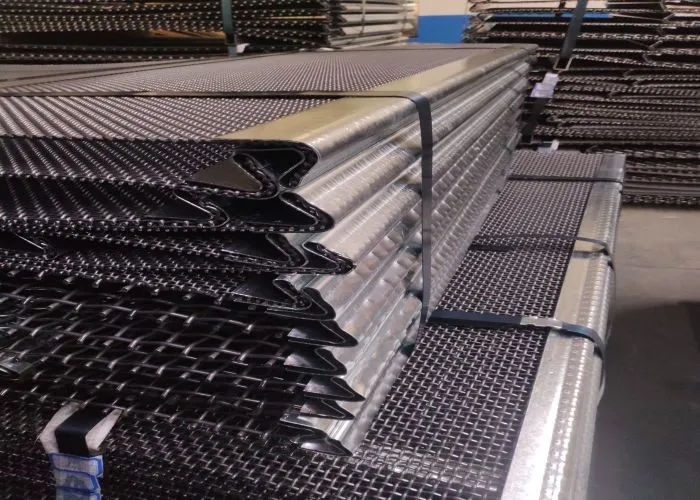

We provide custom sizes, edge preparations, and side clamps to ensure a perfect fit for any screening machine. With consistent performance, long service life, and robust construction, our vibrating screen mesh ensures efficient material flow and reduced downtime in continuous operations.

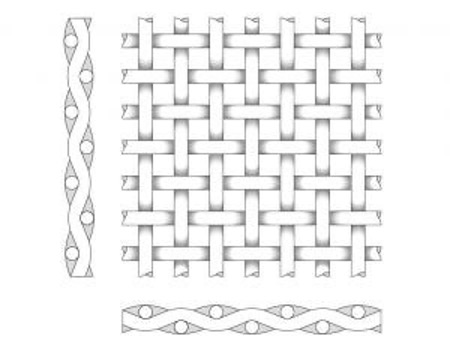

Plain weave:This is the simplest and most common type of woven wire mesh. In plain weave, each wire alternately passes over and under the adjacent wires in both the horizontal (weft) and vertical (warp) directions.

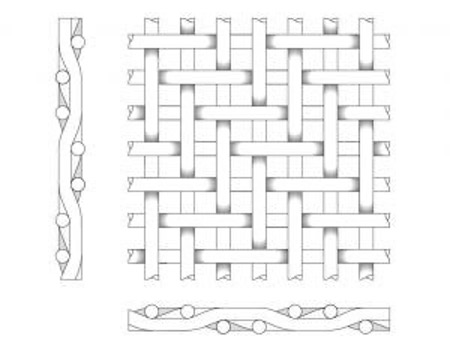

Twill weave: This type of weave creates a diagonal pattern in the mesh. It is formed by passing each weft wire alternately over two and then under two warp wires. This weave creates a tighter mesh with a higher wire count per inch, making it ideal for filtration applications.

| Aperture (mm) | Wire Diameter (mm) |

|---|---|

| 8 | 4 |

| 9 | 4 |

| 9 | 5 |

| 10 | 4 |

| 11 | 4 |

| 11 | 5 |

| 12 | 4 |

| 12 | 5 |

| 12 | 6 |

| 13 | 5 |

| 13 | 6 |

| 14 | 5 |

| 14 | 6 |

| 15 | 5 |

| 15 | 6 |

| 16 | 5 |

| 16 | 6 |

| 17 | 6 |

| 18 | 6 |

| 20 | 6 |

| 24 | 6 |

| 26 | 6 |

| 20 | 8 |

| 22 | 8 |

| 23 | 8 |

| 24 | 8 |

| Aperture (mm) | Wire Diameter (mm) |

|---|---|

| 26 | 8 |

| 28 | 8 |

| 30 | 8 |

| 32 | 8 |

| 34 | 8 |

| 36 | 8 |

| 38 | 8 |

| 40 | 8 |

| 42 | 8 |

| 46 | 8 |

| 50 | 8 |

| 52 | 8 |

| 55 | 8 |

| 28 | 10 |

| 30 | 10 |

| 32 | 10 |

| 34 | 10 |

| 35 | 10 |

| 38 | 10 |

| 40 | 10 |

| 44 | 10 |

| 45 | 10 |

| 50 | 10 |

| 55 | 10 |

| 60 | 10 |

| 65 | 10 |

Vibrating screen wire mesh is typically made from high-quality spring steel (high carbon) material, which is known for its durability and strength. Material sourced from TATA or USHA MARTIN specially engineered for crimping and weaving.

Vibrating screen wire mesh can be used in a variety of applications, such as in mining, quarrying, and construction, among others.

Vibrating screen wire mesh is available in a range of sizes and openings to suit different requirements and can be customized to fit specific dimensions as needed. Can be made to sizes of various OEM like Metso, Puzzolana, Sandvik Asis, Propel, Hailstone.

Vibrating screen wire mesh is designed to provide efficient screening of various materials, including aggregates, minerals, and other substances.

Vibrating screen wire mesh is typically easy to install and can be attached to the screen frame using clamps or other fastening mechanisms.